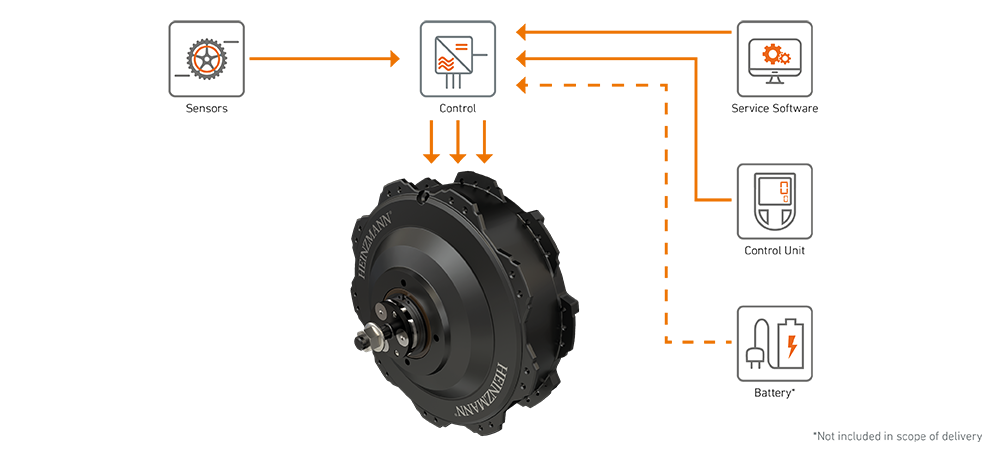

System overview

System Overview CargoPower

Service-Software

The HEINZMANN service software for bicycle drive systems allows convenient and fast configuration of the system using a clear display unit. This makes easy configuration by the manufacturer possible. All the major system parameters can be configured.

The system also provides precise error identification and allows changes to be made at any time, including in the field. Protection against factory data manipulation is also implemented.

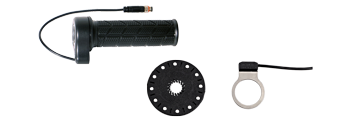

Sensors

The sensors in the CargoPower system include at least a cadence sensor and a twist grip. A control button is also available for reversing.

Versions with a torque sensor are possible as an option. This can either be integrated into the bottom bracket or directly in the hub.

Battery

The Heavy Duty battery can be fitted at almost any location.

The lithium ion high-performance battery is water-tight, shock proof and vibration-resistant. Passive cell balancing increases its service life.

Operating unit

The operating unit is used to make all settings and issue commands to the drive system. It can be fitted on either the right or left of the handlebars and easily changed over so the display is on the correct side.

An intuitive display unit and convenient display functions for the operating status provide extensive information about operation, e.g. speed or range. An integrated Bluetooth 4.0 module makes it smartphone-compatible. A micro USB interface is used to connect to the service tool and also provides a charging function for smartphones.

System CargoPower Controller

The control of the CargoPower system is contained in a separate housing.

The control uses CAN bus to communicate with the battery and display, as well as other peripherals such as the twist grip or torquesensor. The driving characteristics can be individually adjusted by the user using a USB interface to meet specific requirements. The electric assisted pull-away feature also supports stop-and-go operation.

As an option, the control allows regeneration, with additional inputs for brake contacts provided for this purpose.

In the CargoTwinPower system, two controllers are used in master / secondary operation.